Educational Aims

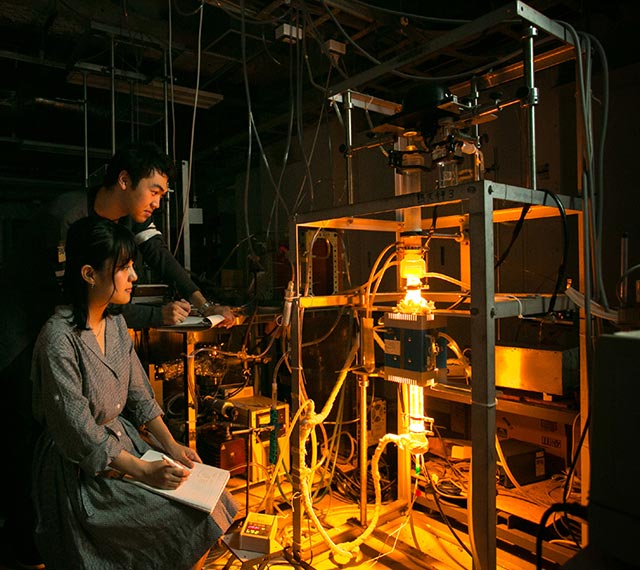

Kinetic analysis of high temperature metallurgical reaction

Materials science and engineering contribute to our society by scientifically understanding the microscopic principles of atoms and electrons that make up materials and by developing the structure, function and characteristics of industrial products through the designing of the microstructures. In the department of Materials, the students will solve problems from a new perspective based on the basic knowledge of materials science and engineering from the refining of raw materials acquired to the manufacturing process and material properties. Also, students will acquire more specialized and sophisticated expertise, more practical experimental technology, and cutting-edge technology development. We establish the following curriculum policy with the goal of training to develop highly creative researchers and engineers who can adapt to changes in the environment.

Master course

- A seamless 6-year integrated curriculum is prepared, which connects from the undergraduate education of the Department of Materials.

- Goal-oriented education with elements of active learning is performed to understand the needs of users going back from the purpose and to think what to learn deeply.

- Education program consists of 4 subjects.

(1)Subject which is subdivided specialized areas, such as raw material refinement, final product structure control and property evaluation, new material creation and process development based on basic knowledge of undergraduate course.

(2)Subject which is deeply understand the concepts and principles that express the physical properties of materials, and learn a wide range of material engineering knowledge and the latest technology.

(3)Subject which is actively collecting social needs, such as organizational control and characteristic evaluation of final products, creation of new materials and process development, by organically collaborating with companies.

(4)Subject which is expand student’s horizons and gain an overall bird's eye view of engineering based on materials.

(U)Analysis of mechanical properties at extremely low temperature, (D)Growth of ceramic crystals

Doctor course

- A research capability will be obtained with high originality in a specific field related to Materials.

- Students will engage in joint collaborative research with a wide range of international researchers, and acquire the world-class research execution ability through interaction with researchers and engineers.

- Education program consists of 2 subjects.

(1)Subject which is develop advanced specialized and academic foundations and practical skills cultivated in the master's program, collect information on cutting-edge research across fields and set research subjects on their own, and deepen further specialized knowledge

(2)Subject which is acquire skills to lead researchers and engineers in the same field with high communication skills through experience of conducting wide range of joint research with domestic and overseas researchers

Admission Policies

In Department of Materials, the student who gained academic achievements in material engineering technology that supports the social environment based on basic studies on material science such as metals, ceramics, semiconductors, etc. and who will grow as a researcher/engineer with a broad perspective is requested.

- Students is required to have knowledge and skills related to material engineering acquired through taking basic courses in the undergraduate department, as well as basic science that supports material engineering.

- The motivation to create and evaluate excellent materials that will be the basis for supporting future society, and to develop and design highly efficient and environmentally-consisted processes is required.

- The leadership in improving energy/environmental problems and promoting material nanotechnology based on advanced medical care and computerization is required.

- The purpose to study of creation of metallic and semiconductor materials, and to understand their physical, chemical, and mechanical properties are systematic from the nano domain (electronic theory, quantum theory) to the macro domain (kinetics, thermodinamics, statistical mechanics, solution theory) is required.

- The ability to think about a scientific phenomenon from multiple sides and convey it to others in their own words, and the attitude to spare no effort to gain broad application, creativity, and internationality is required.

- Attitude to learn in collaboration with diverse people, tolerance to empathize with different ideas, and willingness to constantly improve themselves is required.

Overviews

The Department of Materials educates students from the understanding of the microscopic behavior of atoms and electrons that compose materials, to the controlling macroscopic processes of materials to the macroscopic concepts and principles that govern the expression of properties. We also educate specialized knowledge about subdivided and advanced material engineering. Our aim is to majorize in the current state of technology related to engineering as a whole, and to develop creative researchers and engineers who can solve various problems from the viewpoint of material engineering with a view to developing a sustainable society.

| Metallurgical Physics and Chemistry | Based on the principle of physical chemistry, the course of Reaction Engineering for Materials deals with development and design of material reaction process for the metal smelting & refining processes, and material fabrications. We also conduct research and provide education for physical chemistry related the reaction engineering. In addition, research on electrochemical surface modification is prepared. |

|---|---|

| Metals Science for Structural Materials | The course of Mechanical Processing for Metals and Composites offers comprehensive education and research on forming processing, melt processing, plastic deformation, microstructure designing, and composite materials for structural materials. In addition, we educate the principles for controlling the microstructure of materials by various phase transformations and the evaluation and development of microstructural analysis methods. |

| Functional Materials Science | Atomic and molecular manipulation, surface reaction control, crystal defect control for the production and evaluation of high-performance semiconductors, metals, ceramics materials, advanced thin film materials and nanoscopic microstructural observation, and furthermore, education on the design and evaluation of new functional materials in harmony with the environment. |

(L)Synthesis of semiconductor single crystal for thermoelectric devices, (R)Setting a fuel cell sample to apparatus

Researches

Metallurgical Physics and Chemistry

- Reaction Control and Processing for Materials Lab.

- Electrochemistry for Materials Processing Lab.

- Physical Chemistry of High-Temperature Melts Lab.

Metals Science for Structural Materials

- Composite Material Processing Lab.

- Structural Materials Lab.

- Crystal Plasticity and Fracture for Strong Solids Lab.

Functional Materials Science

- Nanomaterial characterization Lab.

- Advanced Functional Materials Lab.

- Powder and Powder Metallurgy Lab.

- Semiconductor Materials and Devices Lab.

- Energy Materials Engineering Lab.

- Thin Film Engineering Lab.