Reaction Control and Processing for Materials

Department of Materials, Faculty of Engineering

Department of Materials, Graduate School of Engineering

Department of Materials, School of Engineering

Our main research target is engineering related to the production of iron, which is a material widely used in all over the world. We aim to optimize the ironmaking process with insights based on a wide range of perspectives and knowledge on various issues such as the environment and resources of the entire earth. In order to contribute to the construction of a carbon-neutral society that is conscious of SDGs, it is indispensable to reduce the carbon content and zero-carbonization of the ironmaking process. The main reason for the emission of carbon dioxide from the ironmaking process is the use of coal-derived coke as a reducing material for reducing iron oxide contained in iron ore. Our laboratory is working on the development of technology to replace coal, which is a fossil fuel, with hydrogen, which is a green energy, and a new ironmaking process that does not use any fossil fuels at all. From the perspective of resource security, we are also developing available resource expansion technology for stably production of high-quality iron, even from inferior ores that could not be used until now, as one of the most important issues. In order to solve these issues, we are conducting research and education using high temperature experimental technology and numerical simulation technology with reaction kinetics, transport phenomena, and thermodynamics as basic disciplines.

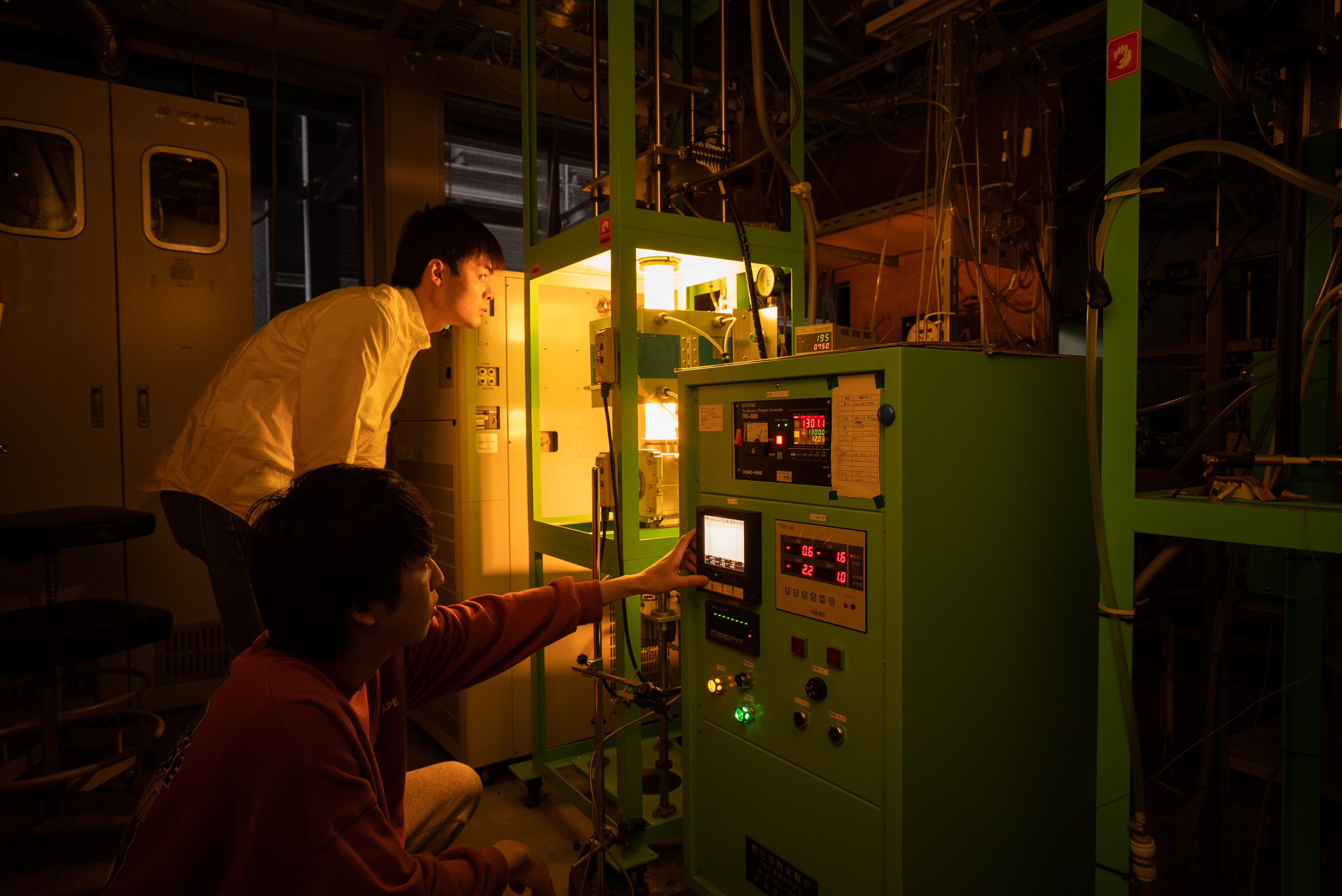

Melting and softening test of iron ore under high temperature conditions

Staff

Prof. Ko-ichiro Ohno

Asst.Prof. Tatsuya Kon

The Main Research Topics

- Low carbonization of ironmaking process by hydrogen blast furnace method

- Development of new carbon-neutral ironmaking method using hydrogen

- Development of available resource expansion technology by pretreatment of low-grade iron ore

- Development of innovative new ironmaking process applying microwave engineering